·

·

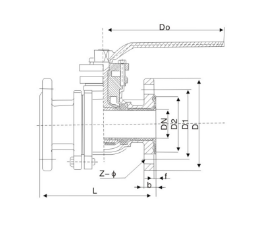

衬氟球阀是用带圆形通孔的球体作启闭件,球体随阀杆绕阀体中心线旋转以实现阀门开启和关闭。采用特殊的模压工艺,使密封面致密良好,加之V型PTFE填料组合使阀门达到零泄漏;球体与阀杆铸为一体,杜绝了由于压力变化引起阀杆冲出承压件内的可能性,根本保证使用中的安全性;采用全塑料衬里工艺,耐介质的强腐蚀。

驱动:衬氟球阀按驱动方式有手动衬氟球阀、蜗轮转动衬氟球阀、气动衬氟球阀、电动衬氟球阀等。

特点:

1.采用氟塑料衬里层的球阀,具有极高的化学稳定性,适用于任何强腐蚀性化学介质;

2.采用全通浮动球阀结构,在整个压力范围内进行元泄漏关闭,便便于管路系统在通球扫线和管路维护。

用途:衬氟球阀为控制各种强腐蚀性介质的启闭而进行的专业设计,广泛使用于石油,化工,染化,农药,制酸制碱等行业,是目前防腐阀门最理想的选择.

| 公称通径 | 主要尺寸 | 参考值 | ||||||||

| ND | NPS | L | D | D1 | D2 | b | f | Z-фd | D0 | H |

| PN1.0MPa | ||||||||||

| 15 | 1/2" | 140 | 95 | 65 | 45 | 3 | 15 | 4-14 | 140 | 90 |

| 20 | 3/4" | 140 | 105 | 75 | 55 | 3 | 17 | 4-14 | 140 | 100 |

| 25 | 1" | 150 | 115 | 85 | 65 | 3 | 17 | 4-14 | 180 | 105 |

| 32 | 11/4" | 165 | 140 | 100 | 75 | 3 | 19 | 4-18 | 180 | 120 |

| 40 | 11/2" | 180 | 150 | 110 | 85 | 3 | 19 | 4-18 | 225 | 140 |

| 50 | 2" | 200 | 165 | 125 | 100 | 3 | 21 | 4-18 | 225 | 150 |

| 65 | 21/2" | 220 | 185 | 145 | 120 | 3 | 21 | 4-18 | 360 | 160 |

| 80 | 3" | 250 | 200 | 160 | 135 | 3 | 21 | 8-18 | 420 | 215 |

| 100 | 4" | 280 | 220 | 180 | 155 | 3 | 23 | 8-18 | 420 | 240 |

| 125 | 5" | 320 | 250 | 210 | 185 | 4 | 24 | 8-18 | 520 | 250 |

| 150 | 6" | 360 | 285 | 240 | 210 | 4 | 26 | 8-23 | 520 | 290 |

| 200 | 8" | 400 | 340 | 295 | 265 | 4 | 26 | 8-23 | 640 | 340 |

| 250 | 10" | 450 | 395 | 350 | 320 | 4 | 28 | 12-33 | 640 | 380 |

| PN1.6MPa | ||||||||||

| 15 | 1/2" | 140 | 95 | 65 | 45 | 3 | 15 | 4-14 | 140 | 90 |

| 20 | 3/4" | 140 | 105 | 75 | 55 | 3 | 17 | 4-14 | 140 | 100 |

| 25 | 1" | 150 | 115 | 85 | 65 | 3 | 17 | 4-14 | 180 | 105 |

| 32 | 11/4" | 165 | 140 | 100 | 75 | 3 | 19 | 4-18 | 180 | 120 |

| 40 | 11/2" | 180 | 150 | 110 | 85 | 3 | 19 | 4-18 | 225 | 140 |

| 50 | 2" | 200 | 165 | 125 | 100 | 3 | 21 | 4-18 | 225 | 150 |

| 65 | 21/2" | 220 | 185 | 145 | 120 | 3 | 21 | 4-18 | 360 | 160 |

| 80 | 3" | 250 | 200 | 160 | 135 | 3 | 21 | 8-18 | 420 | 215 |

| 100 | 4" | 280 | 220 | 180 | 155 | 3 | 23 | 8-18 | 420 | 240 |

| 125 | 5" | 320 | 250 | 210 | 185 | 4 | 24 | 8-18 | 520 | 250 |

| 150 | 6" | 360 | 285 | 240 | 210 | 4 | 26 | 8-23 | 520 | 290 |

| 200 | 8" | 400 | 340 | 295 | 265 | 4 | 26 | 12-23 | 640 | 340 |

| 250 | 10" | 450 | 405 | 350 | 320 | 4 | 28 | 12-26 | 640 | 380 |

DN200以上D0尺寸为涡轮手轮尺寸,DN200以下D0尺寸为手柄尺寸

机械标准是(JB78)时为4孔。

| 公称通径 | 主要尺寸 | 参考值 | ||||||||

| ND | NPS | L | D | D1 | D2 | b | f | Z-фd | D0 | H |

| PN2.5MPa | ||||||||||

| 15 | 1/2" | 140 | 95 | 65 | 45 | 3 | 15 | 4-14 | 140 | 90 |

| 20 | 3/4" | 140 | 105 | 75 | 55 | 3 | 17 | 4-14 | 140 | 100 |

| 25 | 1" | 150 | 115 | 85 | 65 | 3 | 17 | 4-14 | 180 | 105 |

| 32 | 11/4" | 165 | 140 | 100 | 75 | 3 | 19 | 4-18 | 180 | 120 |

| 40 | 11/2" | 180 | 150 | 110 | 85 | 3 | 19 | 4-18 | 225 | 140 |

| 50 | 2" | 200 | 165 | 125 | 100 | 3 | 21 | 4-18 | 225 | 150 |

| 65 | 21/2" | 220 | 185 | 145 | 120 | 3 | 23 | 8-18 | 360 | 160 |

| 80 | 3" | 250 | 200 | 160 | 135 | 3 | 25 | 8-18 | 420 | 215 |

| 100 | 4" | 280 | 235 | 190 | 155 | 3 | 25 | 8-22 | 420 | 240 |

| 125 | 5" | 320 | 270 | 220 | 185 | 3 | 28 | 8-26 | 520 | 250 |

| 150 | 6" | 360 | 300 | 250 | 210 | 4 | 30 | 8-26 | 520 | 290 |

| 200 | 8" | 400 | 360 | 310 | 275 | 4 | 32 | 12-26 | 640 | 340 |

| 250 | 10" | 450 | 425 | 370 | 330 | 4 | 34 | 12-30 | 640 | 380 |

| Class150 | ||||||||||

| 15 | 1/2" | 110 | 89 | 60.5 | 35 | 3 | 15 | 4-15 | 140 | 90 |

| 20 | 3/4" | 117 | 98 | 70 | 43 | 3 | 15 | 4-15 | 140 | 100 |

| 25 | 1" | 127 | 108 | 79.5 | 51 | 3 | 15 | 4-15 | 180 | 105 |

| 32 | 11/4" | 140 | 117 | 89 | 64 | 3 | 15 | 4-15 | 180 | 120 |

| 40 | 11/2" | 165 | 127 | 98.5 | 73 | 3 | 16 | 4-15 | 225 | 140 |

| 50 | 2" | 178 | 152 | 120.5 | 92 | 3 | 17 | 4-19 | 225 | 150 |

| 65 | 21/2" | 190 | 178 | 139.5 | 105 | 3 | 19 | 4-19 | 360 | 160 |

| 80 | 3" | 203 | 190 | 152.5 | 127 | 3 | 20 | 8-19 | 420 | 215 |

| 100 | 4" | 229 | 229 | 190.5 | 157 | 3 | 24 | 8-19 | 420 | 240 |

| 125 | 5" | 254 | 254 | 216 | 186 | 4 | 25 | 8-22 | 520 | 250 |

| 150 | 6" | 267 | 279 | 241.5 | 216 | 4 | 27 | 8-22 | 520 | 290 |

| 200 | 8" | 292 | 343 | 298.5 | 270 | 4 | 30 | 8-22 | 640 | 240 |

| 250 | 10" | 330 | 406 | 362 | 324 | 4 | 32 | 12-25 | 640 | 380 |

DN200D0尺寸为涡轮手轮尺寸DN200以下D0尺寸为手柄尺寸

浙公网安备 33030302000821号

浙公网安备 33030302000821号